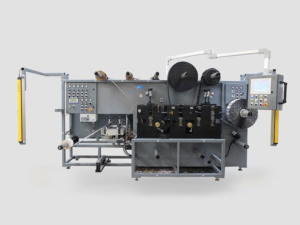

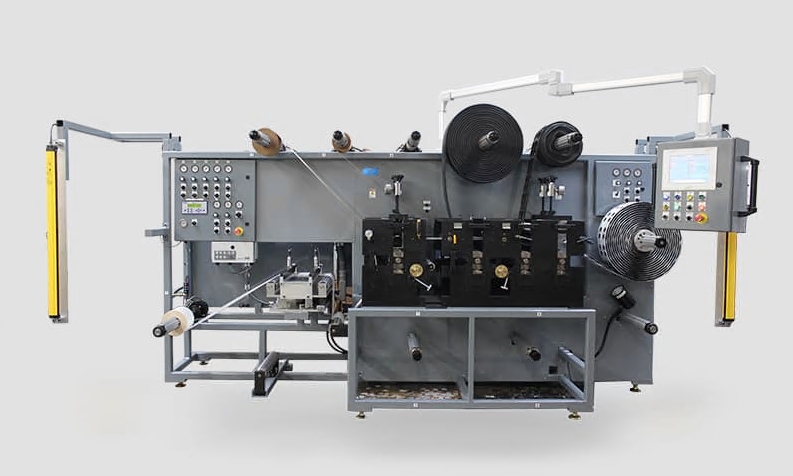

Changeover from one project to another with easy set-up, while maximizing your output by minimizing downtime.

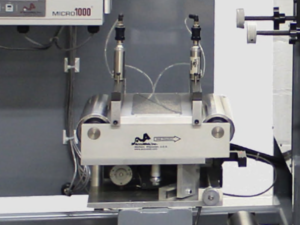

The PACER is very adaptable. With large, removable anvils, it can be used for laminating projects, island placement projects, and other fabricating challenges. Automatic Registration broadens the range of possible converting operations.

Contact a PACE sales representative today to get a quote, or learn more by scheduling a demo at our showroom.

Download Brochure

Additional Information

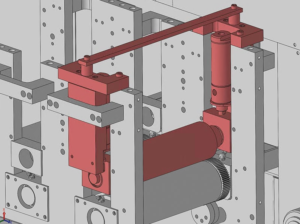

PACE has a full line of options and accessories for our equipment. Servo Motion Control, adjustable stripe guides, lay-on rollers, die pressure truck units and a host of other options can customize your machine for your specific production operations. Spare rollers, die blocks and other inventory parts can keep you operating in emergency situations. Contact us to discuss your specific needs.

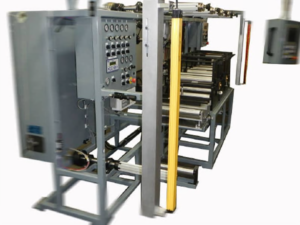

- Four overhead unwinds

- Built-in pneumatic splice table

- Pneumatic pressure nip

- CouAutomatic tension controlsnter

- Safety Light Curtain

- HMI Touch Screen

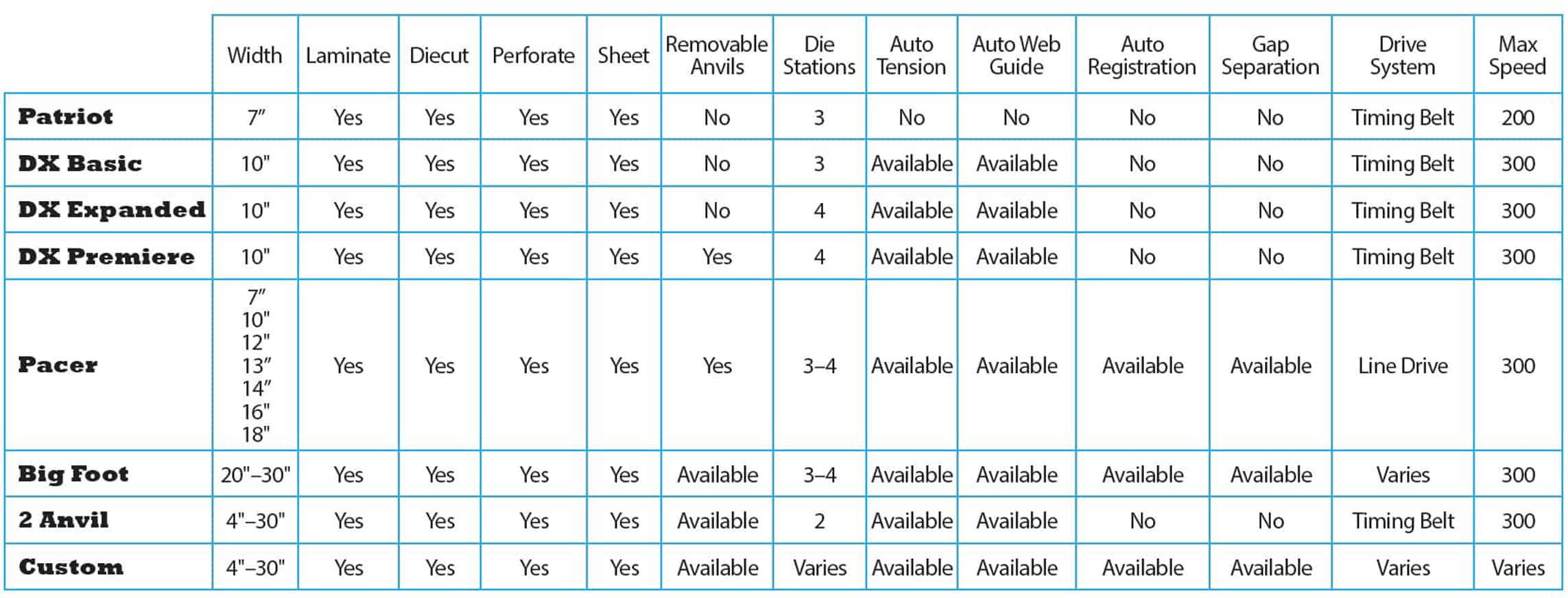

Technical Specifications

Options & Accessories

- Laminate

- Diecut

- Perforate

- Sheet

- Takeoff/Conveyor

- Die Stations 3-4

- Removable Anvils

- Auto Web Guide Available

- Auto Registration Available

- Gap Separation Available

- Drive System Line Drive

Compare

It’s Payback Time!

Contact PACE for more information about our cost-effective, FAST PAYBACK rotary converting machines.